Iron processing | Britannica

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned.Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth’s crust, and it is the ...

Ore Dilution & Recovery in Mining

Recovery and dilution usually are interrelated; with some methods of stoping a high recovery involves contamination of the ore from the walls or capping, and often clean ore can be obtained only by leaving some ore in the mine. In open-stope mines the greatest loss of ore is that tied up in pillars left for support of the back or hanging wall. The amount of ore thus left varies considerably ...

Steps For The Recovery Of Iron From Mining

the major steps of mining iron – Grinding Mill China. mining iron ore step by step process and conveyors – Coal … Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing, major step in taconite ore processing.steps for the recovery of iron from mining…

Mining of Iron Ores – IspatGuru

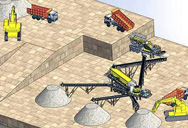

The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state. It consists of several distinct steps. The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and value of the ore body.

Iron Mining Process - Minnesota Iron

Iron Mining Process. From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel. Blasting Taconite is a very hard rock. Using explosives, the taconite is blasted into small pieces.

steps for the recovery iron from ore dressing

The iron content of iron ore, total iron general calculation, can be expressed as TFe, unit for the percent content. The original content of magnetite ore are generally in more than 10% can be mined, generally concentrate grade requirements reach 63 or more 65% to sale; hematite, limonite mining grade general reach more than 30%, the ...

recovery of iron major steps in process

steps for the recovery of iron from mining. the recovery of iron the major steps in processing. major steps involved in mining iron . the iron mining process step by step . major steps involved in open pit mining process of ironThe ores from the major mines iniron ore mining iron is an . Steps from mineral exploration to a mine Step 8 If the ...

the recovery of iron the major steps in processing

the recovery of iron the major steps in processing- the ... The Mining Process Waihi GoldThe Mining Process 1 Mining open pit and underground To define the ore from the waste rock samples are taken and assayed -the major steps in the process of open pit mining for iron-,major steps involved in open pit mining process of ironThe Major Steps In The Process Of Open Pit Mining For The Major Steps …

steps for the recovery of iron from mining

steps for the recovery of iron from mining. Iron processing Britannica. Iron processing use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron Fe is a relatively dense metal with a silvery white ...

9 Step Process for Discovering, Mining & Refining Gold

Jan 23, 2012 · Step #6 – Mining samples and determining processing. Once mining gets underway, samples must be taken to determine the precise metallurgical qualities of the ore. This is done in order to determine the appropriate processing technique. Step #7 – Processing (on-site) Once ore is extracted, processing it into pure gold must be done.

Iron ore - Wikipedia

See also: Environmental impact of iron ore mining. Lower-grade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities.

Pandemic exacts toll on iron-ore sector, but prognosis for ...

The iron-ore sector has been considerably affected by the Covid-19 pandemic, with the worst of the repercussions expected this year; however, there are signs of recovery moving forward. Global ...

Mining - Wikipedia

The process of mining from discovery of an ore body through extraction of minerals and finally to returning the land to its natural state consists of several distinct steps. The first is discovery of the ore body, which is carried out through prospecting or exploration to find and then define the extent, location and value of the ore body.

(PDF) Underground mining Methods - ResearchGate

Stoping with an air drill in an American iron mine in the 20 ... Breast stoping lacks the charact eristic "steps" of either un ... Room-and-pillar mining method has a low recovery ...

Mineral Processing Solutions

The process of refining bauxite to produce alumina (the Bayer process) can traditionally be considered in the following steps: Extraction →Precipitation →Calcination. Extraction. Bauxite ore is crushed and milled to reduce the particle size, making the extraction step more efficient.

Geology, Prospecting and Exploration for Iron Ore Deposits ...

Apr 09, 2015 · Exploitation of existing iron ore deposit is the easier part of the mining operations. The harder part is to find new ore deposits and to define their extent and the iron content (grade). Exploration is the process by which the accumulations of iron ore minerals can be found in the earth’s crust.

Mineral processing - Wikipedia

This separation technique can be useful in mining iron as it is attracted to a magnet. In mines where wolframite was mixed with cassiterite, such as South Crofty and East Pool mine in Cornwall or with bismuth such as at the Shepherd and Murphy mine in Moina, Tasmania, magnetic separation was used to separate the ores. At these mines a device ...