Aggregate Crusher - Turn Stone Materials into …

sand making machine materials Aggregate Crushing Plant: A aggregate plant consists of many crushing and screening equipments. For example, Aimix’s aggregate crush plant is composed of jaw crusher, cone crusher, impact crusher, sand making machine and vibratory sieve. All these machines work in different crushing or screening processing stages. As we have said, jaw crusher is …

Aggregate Crushing - Aggregate

Vibe Convener beltThese straps are often very long and help out with carrying aggregates for crushing to different crushers. Raw materials like pieces of rock are compiled into dumpers and then spread watchfully over the vibrating conveyor belts. The gear vibrates because it gathers smaller pieces of stones and maintains the more expensive pieces to get into the crusher at once.2. Chin CrusherThis …

Raw Material For Crushed Sand - kuchyne …

Aggregate industrial raw materials used for roads and. Natural aggregates (crushed stone, sand and gravel) and industrial minerals are among the most abundant natural resources and a major basic raw material used by construction, agriculture, and industries employing complex stone and metallurgical processes. Right Rocks! Highest grade crushed crystals, rocks, and . Right Rocks creates and ...

AGGREGATE MATERIALS | Newport Materials

Newport Aggregates mines, processes, manufactures, and sells various types and sizes of crushed stone and aggregate product to contractors, material manufacturers, as well as general retail. Our approved aggregate products have been an integral part of many regional construction projects for years, in addition to being used as raw material in asphalt and cement concrete production.

raw feed size of gravel for aggregate crushing

Raw Feed Sie Of Gravel For Aggregate Crushing. Raw material for sand crushing plant. Crusher plant is a complete aggregate crushing processing which can be divided into the jaw impact cone crushing plant portable mobile crushing station quarry crushing plant Crushing materials that include rock puolana gravel limestone coal iron ore construction and demolition wastes and other mineral raw ...

raw material for crushed sand - gestionedeiturni.it

Aggregate - industrial raw materials - used for roads and . Natural aggregates (crushed stone, sand and gravel) and industrial minerals are among the most abundant natural resources and a major basic raw material used by construction, agriculture, and industries employing complex stone and metallurgical processes. More. Sand Crush at Best Price in India. To meet the precise requirements …

Crushing Equipment 101 | Kemper Equipment

The mining and quarrying industry is one of the largest users of crushing equipment. Raw material is blasted or harvest from deep underground. For these materials to be profitable, they have to go through an extensive material handling system. The material is moved from the mine, fed into a crusher, than screened to separate the particles. Crushing equipment works hand-in-hand with all of the other …

raw material for crushed sand - ladonatella.be

raw material for crushed sand california heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for . ...

11.19.1 Sand And Gravel Processing

produce crushed aggregate, or to produce manufactured sands. Crushing generally is carried out in one or two stages, although three-stage crushing may also be performed. Following crushing, the material is returned to the screening operation for sizing. The material that passes through the scalping screen is fed into a battery of sizing screens, which generally consists of either horizontal or ...

Procedures for Aggregate Inspection 06172019

for aggregate materials as standardized by the Michigan Department of Transportation (MDOT). Many, but not all, situations the technician encounters will be covered. Adherence to the procedures contained herein will ensure that tests performed by numerous individuals on the same lot of aggregate materials will be in substantial agreement. The technician conducting the inspection can be a ...

5 Types Crushing Equipments For Sand And …

Crushing equipment can be divided into two categories according to its working principle: 1.Extrusion crushing equipment, such as jaw crusher, rotary crusher, cone crusher, etc. It is suitable for crushing raw materials with a high abrasion index. The content of stone powder in products is low, but generally, the crushed materials have many ...

Crusher - Wikipedia

In operation, the raw material (of various sizes) ... Compound cone crusher (VSC series cone crusher) can crush materials of over medium hardness. It is mainly used in mining, stone industry, road and bridge construction, building, etc. As for VSC series cone crusher, there are four crushing cavities (coarse, medium, fine and superfine) to choose. Compared with the same type, VSC series ...

Construction aggregate - Wikipedia

Construction aggregate, or simply aggregate, is a broad category of coarse- to medium-grained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates.Aggregates are the most mined materials in the world. Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as ...

Aggregate Crushing Plant | How to Run a …

How to Run an Aggregate Crushing Plant? At the same time of economic development, the concrete industry is booming, aggregate sand takes an 80% proportion in all materials of concrete. Improving the productivity of aggregate processing plant, which on the sand aggregate manufacturing process put forward higher requirements. 1 Aggregate processing plant design 1.1 Crusher. How many times a raw ...

Aggregate Crushing Plant For Sale - High …

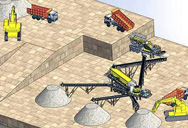

In general, the working process of aggregate crushing equipment is as follows: Obtain the stones or other raw materials by mining or blasting; then obtain the building aggregate by multiple crushing; finally transport these building aggregates to construction projects for using of …

Aggregate Crushing Plants | General Machinery

Aggregate crushing plants are used in the production of raw materials in many industries and these crushing plants are the backbone of industrial sector. First of all, it will be much more helpful to explain what is Aggregate and this will give more advantage to us for explaining related questions. Aggregate is basically a mixture of minerals, or a mixture of minerals called sand, gravel and ...

Brief introduction AGGREGATE CRUSHING PLANT …

02.11.2009 · The raw materials are first put into elementary-crushing machine for crush, then the belt conveyor transfers the elementary products to the secondary-crushing machine for secondary crush.

raw material crushingraw materials crusher

raw materials for aggregate crushing raw materials for aggregate plant Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, rock, quarry .... know more. Crushing of raw materials for cement crushing of cement raw material, jaw crusher - YouTube 12 Feb 2014 , More details: , From raw materials to cement Extracting raw materials Raw ...

Raw material delivery Midcoast Maine. Crushed …

Raw material delivery to Rockland, Rockport, W. Rockport, Thomaston, Owls Head, S. Thomaston, Warren, Camden, Spruce Head, Tenants Harbor, Cushing, Port Clyde ...

Stockpiling | Loading & Hauling stone | Chamney …

The aggregate screening process separates materials. Raw materials pass through a vibrating screen box that contains different screen and mesh sizes. The material falls through like a sieve, and each rock size falls onto an attached conveyor, which stock piles each product, organizing them at the end for hauling. Screening can be used to create sand, gravel, crushed stone, coal, and topsoil. Backhoe, Dozer…