water cooling system for cone crusher - …

water cooling system for cone crusher. World Highways - Maximising cone crusher efficiency. ... HP Series Cone Crushers - liming. system with a fixed return point makes sure that the crusher setting is instantaneously maintained even after passing a piece of tramp iron.

cooling system cone crusher - Out of Africa Lodge

liming Cone Crushers - liming Mining and Construction. adjustment with the Hydroset system • Can be equipped with automatic ... The liming CS- and CH-series of cone crushers have a ..... cooling and heating. Chat Online Kubria® Cone Crusher > Crushers > Mineral Processing > Mining ... Kubria® Cone Crusher.

Cone Crusher Oil Coolers - Cone Crusher Oil …

Manufacturer of Cone Crusher Oil Coolers - Cone Crusher Oil Cooling System offered by AKG India Private Limited, Coimbatore, Tamil Nadu.

AKG India Private Limited, Coimbatore - …

Manufacturer of Cooling System, Cone Crusher Oil Coolers & Air Oil Water And Hydraulic Oil Swivel Joints offered by AKG India Private Limited from Coimbatore, Tamil Nadu, India

coolant system in cone crusher

44SBS Cone Crusher, Portable style lube package, Air-to-Cooling system, Anti-spin system Cold Weather Package, Liners, 3 Phase 60Hz 480 V Call Danny for... More details » Get Price World Highways - liming Constructions new CH550 cone crusher

Maintenance of Hydraulic System of Cone Crusher …

1. The crusher prevents excessive oil temperature. The temperature of the hydraulic system of the hydraulic cone crusher is generally suitable in the range of 35 °C - 60 °C according to the experiment, and the maximum should not exceed 80 °C. At normal oil temperatures, the crusher hydraulic oil has a variety of properties.

Oil Cooling System For Cone Crusher Chile Copper …

Oil Cooling System For Cone Crusher Chile Copper Crusher. At last the HP series cone crusher machine adopts integrated frame castings the integration of thin oil lubrication system lubrication more efficient saving lubricating oil at the same time Big capacity long service life HP horizontal shaft speed up to rmin production increased by laminated effect is better better stone type full ...

Cone Crushers - Mineral Processing & Metallurgy

The working principle of Cone Crushers is explained to understand what application to best use the fine cone crusher in.

liming® MP2500™ cone crusher - liming

limings liming® MP2500 cone crusher brings cone crusher performance to a new level. MP no longer stands for Maximum Power, but now MP is Maximum Performance. limings liming® MP2500 cone crusher still does provide the highest crushing power for any cone crusher in similar size. Advanced crushing dynamics leads to more work per cycle.

cone crusher lubrication system - YouTube

21-10-2016 · hydraulic cone crusher working principle - Duration: 0:42. Mining machinery/Stone Crusher 12,277 views. ... Lubrication System Walk Through - Duration: 1:51. Sloan Lubrication Systems …

Cone Crusher working principle - YouTube

31-8-2015 · Gyratory Crusher Lube System - Duration: 2:05. 911 Metallurgy Corp. 20,488 views. ... H Series Hydraulic Multi-Cylinder Cone Crusher(Trituradora de cono serie H) - Duration: 1:17.

QS331 CONE CRUSHER - liming Mining and Rock Technology

Cone – Fitted with the proven CS430 liming cone for strength – Equipped with Hydroset CSS regulation system for Pressurised cone prevents dust ingress into the cone internals – Various bush settings available to optimize product gradation and capacity – Variable crusher speed via the engine to manipulate product gradation Steel pipework

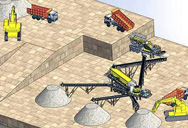

cooling system stone crusher | Mobile Crushers all …

cooling system stone crusher. Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand.

liming Cone Crushers — liming Mining and …

liming cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydroset™ system, which provides safety and setting-adjustment functions. Our crusher automation system delivers real-time performance management, enabling you to monitor and optimize crusher performance and productivity.

14 Cone Crusher Common Problems And How To …

The cone crusher can not be restarted immediately when it stops suddenly, so as to avoid secondary damage to the cone crushing production line. First of all, you should find out the reasons for the sudden stop of the cone crusher, there are 5 common reasons: 1.

What Is A Hydraulic Cone Crusher? - HongXing …

5-12-2019 · The biggest advantage of hydraulic cone crusher—hydraulic system hydraulic controlling part. This hydraulic system controls the movement of 3 basic circuits. One is the action of the fixed cone hydraulic locking hydraulic cylinder, the second is the hydraulic motor that adjusts the gap between the moving and fixed cone.

Portable Cone Plants | Portable Plants | Telsmith

38SBS Cone Crusher — 150 kW (200 HP) 44SBS Cone Crusher — 220 kW (300 HP) including: Air-to-Oil Cooling System: Dynamic Bowl Adjust Titan™ Series Cone Crushers 300-400 HP: Simple and Safe Hydraulic Relief and Clearing

Py cone crusher for coal mining with water cooling

Py cone crusher for coal mining with water cooling. sample rom pad feed to crusher How To Coal Crusher Feeding testrigin water in coal feed to crushers Crushing reduces the overall topsize of the ROM coal so that it can be Jaw Crusher sample preparation in lab [email ... Cooling System Stone Crusher.

operating pressure of cooling oil in cone crushers

MP cone crushers perform consistently, no matter what the ... mining operations, the MP1000 and MP800 .... mum head support and multiple oil grooves for full... Chat Online liming T900 Cone Crusher. Air-to-oil cooling system. • High ambient air-to-oil cooling system ... liming T900 Cone Crusher ... 8 cylinder, 172 Bar [2,500 PSI] hydraulic ...

Crusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.