Discharge Opening of Jaw Crusher

Generally, the check of jaw crusher discharge opening can be carried out through lead ball (or lead block). In order to hold the lead block conveniently, we can cast it into a small ball or cylinder. And cast the iron wire into the occlusion of the lead ball so that we can carry it and put it into the crushing cavity.

What is a Jaw Crusher? | Telsmith

A jaw crusher is a compression type crusher, comprised of a fixed jaw and moving jaw positioned in a (V). The movable jaw compresses material against the fixed jaw, crushing the material to the desired size. The material exits the jaw through the bottom of the crusher otherwise known as the discharge opening.

Jaw Crushers | McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

ASC Scientific Laboratory Jaw Crusher - ASC Scientific

ASC Scientific Laboratory Jaw Crusher ASC Scientific’s high capacity laboratory jaw crushers are extremely rugged and incorporate many design improvements over previous models. 1/2 HP Baldor fully enclosed motor 3″ x 2″ feed opening

Jaw crushers - liming

liming® C Series™ jaw crushers have an aggressive motion of the pitman and long stroke in the bottom of the cavity. A larger feed opening increases material intake and ensures that the rocks enter the jaw crusher’s cavity without restrictions.

Jaw crushers, Stationary Jaw crusher series — liming ...

Stationary jaw crushers. liming jaw crushers are of the single-toggle type with advanced features for optimized performance, easy maintenance, long life and a low cost per ton. These crushers feature a deep, symmetrical crushing chamber, easy settings adjustment, a large feed opening for its size, and an ideal nip angle that offers smooth material flow and high reduction efficiency.

Complex Opening Report Pendulum Jaw Crusher In The Topic Based

Feb 25, 2018 · Complex Opening Report Pendulum Jaw Crusher In The Topic Based. A dictionary fileictfilesengcomc this class can parse, analyze words and interprets sentencest takes an english sentence and breaks it into words to determine if it is a phrase or a clauset can also counts the total number of words in a sentence, checks if a word is a palindrome and can generate a new sentence …

Measuring the crusher setting

The opening of the primary crusher, for example, will affect the throughput of secondary crushing, and secondary crushing will, in turn, influence tertiary production and so on. How to check the opening of the jaw crusher Whenever a jaw crusher is off and at rest (stopped), it will remain in the open position at its open-side setting (OSS).

Industrial Solutions Jaw crushers

Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate.

ASJ-E Series Jaw Crusher(Sino-Japanese Cooperation ...

Features 1.“V” type of crushing chamber, effective opening size is equal to the nominal opening size (common jaw crusher adopts the traditional asymmetric crushing chamber structure, and effective opening size is smaller than nominal opening size)and the throughput capacity will be increased by15-20% compared with the normal crushing chamber.

Cause Jaw Crusher Is Less Than Expected

2, feed speed faster, because different types of jaw crusher device processing capacity is limited, in production, when the various aspects of the parameter set time, if the fast feed speed is set, then the lower chamber of the deviceplot material too, clogging the discharge opening, then the phenomenon of less than expected;

Jaw Crusher | Primary Crusher in Mining & Aggregate - JXSC ...

It uses curved plates to avoid the near the discharge of jaw crusher blocking. The bottom of the swinging jaw is concave, and the relative lower part of the fixed jaw is convex. The materials reduction in size when nears the exit. So the material is distributed over a larger area, and the jaws plates wear less.

how a jaw crusher works and what it is used for

A Jaw Crusher is one of the main types of primary crushers in a mine or ore processing plant. The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws (feed opening). For instance, a 24 x 36 jaw crusher has a opening of 24" …

Jaw Crusher Circuit Open

Jaw Crusher Circuit Open Abstract. Jaw Crushers CircuitJaw Crushers Circuit. Jaw crusher - an overview sciencedirect topics.Primary jaw crushers typically operate in open circuit under dry conditions.Depending on the size reduction required, the primary jaw crushers are followed by secondary and tertiary crushing.The last crusher in the line of operation operates in a closed circuit.Crusher ...

Crusher - Wikipedia

A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber.

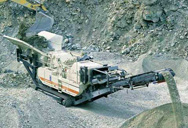

Jaw Crusher | Mining Quarrying and Recycling | Powerscreen

Jaw Crushers Powerscreen jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying and recycling industries. These machines are amongst the most advanced and reliable in the market and are highly productive in a variety of applications.