Iron ore

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red.

Ore Processing - Feed The Beast Wiki

88 Zeilen · Ores of chemically pure materials can be processed in 1.11 of Ingot for 1 Ore (f.e. Iron), …

Ore processing - Industrial-Craft-Wiki

8 Zeilen · 16.12.2016 · A Macerator processes ore - iron, gold, copper, tin, lead, and uranium - into …

wiki iron ore processing

Ore Processing is the process of multiplying ores to create more ingots. Mekanism ore processing works on Iron Ore, Gold Ore, Osmium Ore, Copper Ore, and Tin Ore. This tutorial will teach you how to set up basic ore processing. If you are not familiar with.

Pelletizing

The formation of raw iron ore pellets, also known as pelletizing, has the objective of producing pellets in an appropriate band of sizes and with mechanical properties high usefulness during the stresses of transference, transport, and use. Both mechanical force and thermal processes are used to produce the correct pellet properties.

Environmental impact of iron ore mining

Iron ore is rock containing enough iron content, and in sufficient volume and accessibility to mining and transportation to be able to be economically mined. Iron in ore iron is most commonly found in the form of magnetite (Fe3O4), hematite (Fe2O3), goethite (FeO(OH)), limonite (FeO(OH)·n(H2O)) or siderite (FeCO3). Roughly 98% of iron ore on the global market is used in iron and steel production. Common methods of extracting the iron ore consist of blasting, drilling, or general excavating, ,. Most ir…

Mineral processing

The first pair of electromagnets was weakly magnetised and served to draw off any iron ore present. The second pair were strongly magnetised and attracted the wolframite, which is weakly magnetic. These machines were capable of treating 10 tons of ore a day. This process of separating magnetic substances from the non-magnetic substances in a mixture with the help of a magnet is called magnetic ...

Ore Processing - Official Mekanism Wiki

Ore processing flowchart (Mekanism 9) Simplified version of flowchart. Tier 0. This is the stock minecraft Tier of directly smelting ores into ingots. First energy is produced for example by Heat Generator in passive mode. 1 Raw Ore → Energized Smelter → 1 Ingot Basic Tier 0 Setup. Tier 1. New machines on this tier: Enrichment Chamber. This tier doubles ingot yield, similar to many other ...

Iron

Iron ore is then treated with these gases in a furnace, producing solid sponge iron: Fe 2 O 3 + CO + 2 H 2 → 2 Fe + CO 2 + 2 H 2 O. Silica is removed by adding a limestone flux as described above. Thermite process. Ignition of a mixture of aluminium powder and iron oxide yields metallic iron via the thermite reaction: Fe 2 O 3 + 2 Al → 2 Fe + Al 2 O 3. Alternatively pig iron may be made ...

Iron Ore | Hydroneer Wiki | Fandom

Iron ore can be obtained from processing dirt. From the 1.3 update the spawn rate is 52%

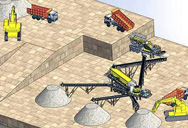

The Six Main Steps of Iron Ore Processing

When the material exits the mill, the iron ore is classified using cyclones or vibrating screens that separate fine and large particles. The large particles are diverted back into the crusher and the fine particles will undergo a spiral gravity separation process. 5.

Iron Ore - Official Satisfactory Wiki

25.08.2020 · Iron Ore is a basic type of ore which is abundant in the world. It is smelted into Iron Ingots for further processing. Its Resource Scanner is unlocked after the engineer leaves the drop-pod.

Iron ore - Factorio Wiki

Iron ore is a resource found on the map. It can be smelted into iron plates in a furnace, and is also a component in concrete.

Iron processing

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties.

iron-ore processing - Deutsch-Übersetzung – Linguee Wörterbuch

Viele übersetzte Beispielsätze mit "iron-ore processing" – Deutsch-Englisch Wörterbuch und Suchmaschine für Millionen von Deutsch-Übersetzungen.

iron ore processing plant - Deutsch-Übersetzung – Linguee ...

Viele übersetzte Beispielsätze mit "iron ore processing plant" – Deutsch-Englisch Wörterbuch und Suchmaschine für Millionen von Deutsch-Übersetzungen.

wiki iron ore processing

Ore processing in IC² is a multi-stage process, requiring several machines in order to get the maximum possible yield from each individual ore. A Macerator processes ore - iron, gold, copper, tin, lead, and uranium - into 2x crushed ore of the corresponding type.

Wed The Process Of Extracting Iron From Its Ore

Wed The Process Of Extracting Iron From Its Ore. Extracting a metal from its ore - chymist.com. In this experiment copper will be extracted from malachite by reaction with sulfuric acid and then reduced from the acid solution using metallic iron. . With the depleting reserves of high-grade iron ore in the world froth flotation has become increasingly important to process intermediate- and ...