RAW MATERIALS IN CEMENT PRODUCTION - …

07-02-2019 · Therefore, there are sludge pools with high and low titer content on cement plants. The sludge from pools is mixed in certain proportions. In this connection, each cement plant has its own, unique composition of raw materials for production of finished goods. For example, a mixture of materials used by some cement plants in Ukraine.

crushing and grinding of raw material in a cement

Raw Material Drying-Grinding - Cement Plant … Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 70-80% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills.

Raw materials - Cement

Raw materials used in cement manufacturing. If you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless you view the clinkering process as igneous rocks in the making.

Raw Material Mill For Cement Plant Photo

Raw material, additive, cement ... The majority of raw materials handled at a cement plant are prone ... and vibrations in vertical roller mills. Cement can be ... raw mill of cement plant complete detail with images. raw mill of cement plant complete detail with images .

raw materials for a cement plant - afaup.it

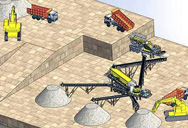

The cement raw materials is formed with calcareous materials, clayey materials and slight corrective material in appropriate proportion, and grinded into certain fineness. The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing .

Raw Materials For A Cement Plant

Raw Materials For A Cement Plant Henan Mining Heavy Machinery Co., Ltd. If you are interested in our company or products, welcome to visit our company and factories; you can also get in contact with us through online customer services, inquiry form, e-mails and telephones.

Raw materials for cement manufacturing

Lime Component Limestone: Common forms of calcium carbonate used as raw material for cement manufacturing are limestone and chalk.Limestone is of predominantly fine grained crystalline structure, its hardness is between 1.8 to 3.0 of the Mohs scale of hardness and specific gravity 2. To 2.8. Limestone usually contains admixtures of clay substance or iron compounds, which influences its color.

Cement Raw Materials used in Manufacturing of …

07-06-2016 · Raw materials used for manufacturing of Portland cement are found naturally in the earth’s crust. It is made primarily from calcareous and argillaceous materials and gypsum. Calcareous materials contain limestone or chalk while argillaceous materials comprise an oxide of silica-alumina and iron. Both are found as clay or shale.

CEMENT RAW MATERIALS - International Cement Review

The raw materials which supply cement works, and which may be required in quantities of over 4,000 tonnes per day, must be thoroughly proven if the plant is to run successfully. Consistent quality feed is required and an extraction plan must be made to ensure that a uniform flow of raw material will always be available to the kilns.

How Cement Is Made - Portland Cement Association

The most common way to manufacture portland cement is through a dry method. The first step is to quarry the principal raw materials, mainly limestone, clay, and other materials. After quarrying the rock is crushed. This involves several stages. The first crushing …

raw materials for a cement plant - dentisti-napoli.it

From raw materials to cement Extracting raw materials Raw material ... The most important raw materials for making cement are lilimingne, clay and marl. ... raw material storage of the cement plant by conveyor-belts, cableways or.

Building Materials Equipment - Raw materials for a …

Building Materials Equipment : Raw materials for a cement plant - Building materials equipment mainly includes cement production equipment, activated lime production equipment, etc., standardized production processes to ensure the smooth operation of equipment and processes, and ensure the interests of customers.

The Raw Materials A Cement Plant Needs - HeNan …

The Raw Materials A Cement Plant Needs. 1. Introduction. The use of wastes in cement manufacturing either as a supplementary fuel or substitute for other raw materials provides an option for simultaneously eliminating waste and recovering energy and materials 12.This concept has been developed and used for co-processing problematic waste such as municipal solid waste MSW sewage sludge ...

Cement Plant Raw Material - zandvoortse4daagse.nl

Cement Plant Raw Material. Circular of the General Office of the State Council on Translate this page. 20040427 20040427 The General Office of the State Council epdf/e04306.pdf A2 fixed asset investment, liquidation, project under construction, project to be . Get Price [DOC] · Web view.

Raw Material Grinding Amran Cement Plant - …

Raw material grinding in a cement plant . ThyssenKrupp Industrial Solutions Cement Industry. Maximum throughput rates and drive powers smallest possible construction sie and high availability are the essential demands on a cement raw material grinding plant and also precisely the characteristics of this new roller mill from Polysius.

raw materials required for cement grinding units

Raw Material Drying-Grinding - Cement Plant Optimization. Grinding Operation Objectives and KPIs: Highly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous, dry (0.5% moisture) and super fine (10-20% residue on 90-micron sieve) raw meal powder for clinkerization process in kiln (Dry Process).). Grinding operation is monitored for foll

Manufacturing process | Home : Lafarge - Cement

The raw materials needed to produce cement (calcium carbonate, silica, alumina and iron ore) are generally extracted from limestone rock, chalk, clayey schist or clay. Suitable reserves can be found in most countries. These raw materials are extracted from the quarry by blasting. They are then crushed and transported to the plant where they are stored and homogenized.

rail incoming raw material cement plant

RAW MATERIALS IN CEMENT PRODUCTION. Therefore, there are sludge pools with high and low titer content on cement plants. The sludge from pools is mixed in certain proportions. In this connection, each cement plant has its own, unique composition of raw materials for production of finished goods.

Cement manufacturing - components of a cement …

Cement is typically made from limestone and clay or shale. These raw materials are extracted from the quarry crushed to a very fine powder and then blended in the correct proportions. This blended raw material is called the raw feed or kiln feed and is heated in a rotary kiln where it reaches a temperature of about 1400 C to 1500 C.