Impact Crusher Working Principle

Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill). Dynamic impact could be described as material dropping ...

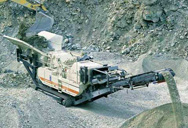

Impact Crusher, Impact Crusher Working Principle

Impact crusher working principle as follows: when the device is working, driven by electric motors, high speed rotation of the rotor. Material entered Board hammer role district Shi, and rotor Shang of Board hammer impact broken, Hou and was throwing to counterattack device Shang again broken, then and from counterattack lining Board Shang play returned to Board hammer role district again broken, …

Working Principle Of Hammer Mill Crusher …

The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these machines ...

Hammer Crusher Working Principle I Cement …

12.04.2018 · Hammer Mill A hammer mill is a crusher that can grind, pulverize, and crush a wide range of materials. This rock crusher machine employs a rain of hammer blows to shatter and disintegrate the ...

Working principle of impact crusher

(see Figure Impact Crusher 1) crusher working principle diagram for a typical counter. Broken material crusher, material is suspended by the plate hammer impact. If the particle size is smaller, the impact force is approximated by a particle of gravity, material along the tangent direction (see Figure Impact Crusher 1) by dotted lines) throw.

Working Principle Of Hammer Crusher

Working principle of hammer roller crusher - wwprojekteuammer mill crusher grinder the hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone.Hammer Mill Working Principle - Hammer CrusherWorking Principle Of The Hammer Mill . The working principle of hammer mills step sep 23 2014hammer mills work in …

Impact Crusher - an overview | ScienceDirect Topics

Hammer (impact) crusher: The feed is fragmented by kinetic energy introduced by a rotating mass (the rotor) which projects the material against a fixed surface causing it to shatter causing further particle size reduction. This crusher produces more rounded shape.

Impact Crusher | Description | Advantages | Types …

15.08.2012 · Working principle of vertical shaft impactor is totally different than horizontal shaft impactor. It has a high speed rotor with wearing resistant tips and main chamber (crushing chamber) is designed in such a way so that speed rotor throw the rocks against the high crushing chamber. In vertical shaft impactor crusher predominant force is the velocity of speed rotor.

hammer crusher, impact crusher - YouTube

30.08.2012 · Jaw crusher, impact crusher, hammer crusher, roller press,etc. Brandon Chow Sales manager Chengdu Xinli Equipment Manufacturing Co.,Ltd www.xinli-posuiji.com [email protected].

Impact Crusher VS Hammer Crusher [7 Pics & 10 …

The plate hammer is used to smash the input material from the bottom to up and throw it onto the upper impact plate. The hammer head of the hammer crusher is used to crush the material (free crushing, impact crushing), and the speed and kinetic energy obtained by the material are limited.

Hammer crusher working principle Research …

WORKING PRINCIPLE OF CLAY CRUSHER MACHINE Clay Crusher Machine the main working parts of the rotor with a hammer. The rotor is composed of main shaft, disk, pin shaft and hammer. Motor drives the rotor in the crushing cavity high-speed... 383 Words 2 Pages

FAM – Crushers – Processing Technology

FAM designed crushers are used for crushing minerals, raw materials and other bulk commodities. The types of crushing machines are distinguished by their working principles: by pressure, impact, hammer, or shear. In contrast to mills, crushers process the feed materials into …

Hammer Crusher - Crusher|Jaw Crusher|Impact …

The Working Principle of Hammer Crusher Materials go into the hammer crusher and crushed by the high-speed rotating hammer. Driven by the hammer, the crushed materials then throw to the crushing plate. And the large size materials are crushed by the hammer in the grate bars and small size ones discharge from the grate bars.