Blasting of 60.000t iron ore at Erzberg - Slow …

22.07.2016 · Blasting of 60.000 tons of iron ore at the Austrian open pit mine "Erzberg". They use approx. 7.000kg explosives for one blast and they do that at least once a day. Created using YouTube Video ...

Iron Ore Blasting Process Videos

Iron Ore Blasting Process Videos Albumt. We can provide our customers the all-sided produce project such as aggregate production line, mineral ore processing plant, sand making plant and other construction recycle plant to satisfy their production request. Get Price And Support. Simply complete the form below, click submit, you will get the price list and a A&C representative will contact you ...

BLAST FURNACE - YouTube

04.10.2016 · blast furnace process for iron making : Iron is extracted from iron ore in a huge container called a blast furnace. Iron ores such as hematite contain iron(III) oxide, Fe 2O 3. The oxygen must be ...

Iron Ore Blasting Process Videos - battleguide.co.za

Iron ores mining videos,iron ores mining process videos , iron ore mining videos iron ores are rocks and mineral deposits from which clanging iron can be reasonably extracted the ores are generally prosperous in iron oxides and fluctuate in color ranging from dark grey, bright yellow, deep purple, to even rusty red 247 online. Get Price; Pdf Rock Blasting In Underground Mining. Rock blasting ...

1.Blasting at Mt Whaleback Iron Ore Mine - …

28.01.2012 · Autoplay When autoplay is enabled, a suggested video will automatically play next. Up next Magnetite Iron Ore blasting, FMG Iron ore mine Pilbara, WA - Duration: 6:45.

Extraction of Iron | Metallurgy | Blast Furnace and …

This concentrated ore is mixed with limestone (CaCO 3) and Coke and fed into the blast furnace from the top. It is in the blast furnace that extraction of iron occurs. The extraction of iron from its ore is a long and subdued process, that helps in separating the useful components from the waste materials such as slag. What happens in the Blast ...

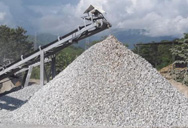

Environmental impact of iron ore mining - …

Mining and processing. Common methods of extracting the iron ore consist of blasting, drilling, or general excavating,,. Most iron ore is produced from open-pit mines. After the iron ore is out of the ground, it may be shipped to the iron and steel manufacturing plant. If the ore contains less than 60 percent iron, it is usually beneficiated to an iron-ore concentrate typically containing ...

Iron Mining Process - Minnesota Iron

From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel. Blasting Taconite is a very hard rock. Using explosives, the taconite is blasted into small pieces. Transportation The taconite pieces are scooped up by electric shovels. Each...

Iron processing | Britannica

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned.Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth’s crust, and it is the ...

DynoConsult, BOT Process Helps Iron Ore Producer Reduce ...

DynoConsult, BOT Process Helps Iron Ore Producer Reduce Blasting Costs . BOT PROCESS AND DYNOCONSULT HELP MAJOR IRON ORE PRODUCER LOWERS COSTS AND INCREASE PRODUCTIVITY . Blasting is one of the least expensive, yet most critical aspects of the overall mining cycle. To gain a better understanding of production costs and to develop a continuing improvement process…

Blast furnace - Wikipedia

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. Blast refers to the combustion air being "forced" or supplied above atmospheric pressure.. In a blast furnace, fuel (), ores, and flux are continuously supplied through the top of the furnace, while a hot blast of air (sometimes with ...

Mining of Iron Ores – IspatGuru

The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state. It consists of several distinct steps. The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and value of the ore body. This leads to a mathematical ...

Drilling Blasting In Opencast Iron Ore Mine

20191219the iron ore that is blasted is stacked and loaded upon large dumpers to be moved to the blast furnaces for smelting processenches are made for the process of iron ore miningechanized mining involves creation of benches that are used for the purpose of drilling, blasting, and finally the transportation of the iron ore to the crushing.